The IGNIS K563 SUPERAUTOMATICA is a 5kg capacity topload washing machine.

This is probabily one of the fascinating washing machines of the world, for design, robustness, programming, washing, easyness of use, reliability, durability, quality, noise........................and everlastingness...............a nice old Italian toploader washingmachine.......................

The IGNIS K563 was fabricated from 1962 to 1968 by IGNIS Italian factory of Giovanni BORGHI and was a very succesful product sold very well.

The IGNIS K563 SUPERAUTOMATICA was first IGNIS Italian washing machine fully automatic and was called for that the

"IGNIS SuperAutomatica"

The innovation concerns an automatic drum washing

machine whose drum up within the machine housing

suspended tub about a horizontal axis and is rotatable in

its perforated shell has a capping by a cover

having bare charging port.The object of the innovation, it is primarily of use

to simplify and maintenance of such a machine and to

facilitate. In particular, all operating controls

be combined into a controller, the appropriate in a

easily accessible location appropriate by the operator

replaceable easily monitored and in case of disturbances easy should be fixable.

The innovation concerns an automatic drum washing

machine whose drum up within the machine housing

suspended tub about a horizontal axis and is rotatable in

its perforated shell has a capping by a cover

having bare charging port.The object of the innovation, it is primarily of use

to simplify and maintenance of such a machine and to

facilitate. In particular, all operating controls

be combined into a controller, the appropriate in a

easily accessible location appropriate by the operator

replaceable easily monitored and in case of disturbances easy should be fixable.When opening the lid a security feature is performed;It is known that in washing machines electrical rotational speed of the rotating parts, for example, the washing machine drum, high values can assume during spin, about 600 revolutions per minute. To accidents prevent, therefore, must the possibility of this high speed rotating parts accidentally touching hands absolutely avoided.

The rotating parts

therefore off by a lockable door generally

covered which is coupled with an electric switch

is, switches off the power supply of the motor as soon as the door is opened. Since a simple turning off of the

Motors in view of the considerable inertia of the rotating parts is generally inadequate, developing eventually such machinery with a mechanical

Brake that is set when you open the door in activity is a solution which may complex and expensive. The invention therefore is an object, an effective accident prevention means a simple and economical way to realize.

This object is achieved by the invention in that a second,

in addition to access to the rotating parts

opening door is provided which likewise with switch to open the first lid door can switch the motor on one of the lower

Speed corresponding poles, for example,

maximum number of poles (Wash speed), after while the switch of

last openable door switches off the motor completely.

The length of time between the opening of the second

Door and the utter standstill of rotating

Parts is, is so short that at normal speed

speed handling touching the rotor

animal parts can be carried out only when they are already

have come to a complete stop. Intentionally

accelerates the process of opening the second door, so

Although the user can touch the rotating parts,

if they are still in motion, however, this loading

movement now so slow that no risk of accident is no longer present or even fully lowered.

The rotating parts

therefore off by a lockable door generally

covered which is coupled with an electric switch

is, switches off the power supply of the motor as soon as the door is opened. Since a simple turning off of the

Motors in view of the considerable inertia of the rotating parts is generally inadequate, developing eventually such machinery with a mechanical

Brake that is set when you open the door in activity is a solution which may complex and expensive. The invention therefore is an object, an effective accident prevention means a simple and economical way to realize.

This object is achieved by the invention in that a second,

in addition to access to the rotating parts

opening door is provided which likewise with switch to open the first lid door can switch the motor on one of the lower

Speed corresponding poles, for example,

maximum number of poles (Wash speed), after while the switch of

last openable door switches off the motor completely.

The length of time between the opening of the second

Door and the utter standstill of rotating

Parts is, is so short that at normal speed

speed handling touching the rotor

animal parts can be carried out only when they are already

have come to a complete stop. Intentionally

accelerates the process of opening the second door, so

Although the user can touch the rotating parts,

if they are still in motion, however, this loading

movement now so slow that no risk of accident is no longer present or even fully lowered.

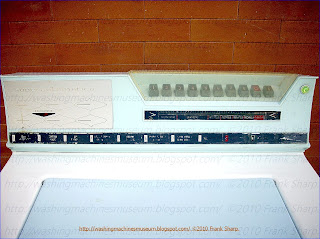

According to the innovation the control and operating the single machine controller it's provided that the upper part the machine housing behind the hinged cover detachable is mounted and a control pushbutton set, at least one Timers and a panel of printed circuits for connections.

Manure contains the pushbuttons set with the to time switch,

the various parts of the machine, namely the motor, pump, etc.

The Controller is electrically connected by cable to the who

displayed one end directly to the parts of the machine

closed and at the other end by means of plug into the control

desk envisaged outlets are plugged.

Manure contains the pushbuttons set with the to time switch,

the various parts of the machine, namely the motor, pump, etc.

The Controller is electrically connected by cable to the who

displayed one end directly to the parts of the machine

closed and at the other end by means of plug into the control

desk envisaged outlets are plugged.

In a particularly advantageous embodiment of the Innovation contains the pushbuttons set individual pushbuttons with the ever numbers a special washing program associated , said on the control panel a list of the proposed Wash programs with corresponding numbers is present.

Further, the controller may have a display scale, whose light pointer indicates the respectively held operation.

It has a pretty unique programming approach were other fabricants have proposed after other automatic washers type with rotary timers. An example was the Italian CASTOR Queenmatic with one rotary timer knob used for even switch ON OFF the machine.

To operate the machine, it is therefore only necessary, to press each eligible pushbutton, whereupon the machine performs automatically the appropriate wash program.

The direct competitor to this kind here above machine was the MIELE 420 and after model MIELE 421 in which one rotatable knob was used to perform program operation choice and power on and off.

Various versions have had developed with even an INOX finitures and INOX TUB called KINOX model, other versions and types were developed for other Italian Brands like RADIOMARELLI LV7, FARGAS 405, CGE, FIDES, ALGOR, SALAMINI S8, but basically all identical to the IGNIS K563 ...........

A further space save version called IGNIS SPAZIALE was developed on the basis of the K563 SUPERAUTOMATICA but with different timer version (HOLZER AOZ151) and without buttons but only rotary selector for the 8 programs.

The machine may be water feeded with warm and cold or only cold water or mixed.

The IGNIS K563 SUPERAUTOMATICA may be easy moved around washing room with the wheel device bottom located which by means of a lever may be pulled to drive the wheel of the floor to help moving it pulling the machine.

When someone finishied positioning the machine the lever may be closed to lock the machine of the floor by its natural hughe weight.

All commands are located above and all programs are selectred through numbered pushbuttons under a transparent lid.

To start a washing program according to load, you have to push the corresponding number and then press the "1" button to wake up the timer which starts running and performs the search to automatically run all needed sequences, indicating on a scala with a left to right moving nail the performed pre washing, washing, rinsing, spin operations of the machine in real time. A further red neon lamp on the left side (pictured as "Riscaldamento" =Heating) indicates when the machines heats up the water at temperatures from 30 to 95° degree.

To start a washing program according to load, you have to push the corresponding number and then press the "1" button to wake up the timer which starts running and performs the search to automatically run all needed sequences, indicating on a scala with a left to right moving nail the performed pre washing, washing, rinsing, spin operations of the machine in real time. A further red neon lamp on the left side (pictured as "Riscaldamento" =Heating) indicates when the machines heats up the water at temperatures from 30 to 95° degree.The upside right green neon lamp (IT'S NOT A LED...............) shows the running of the program and turns off at the end of the program.

If you open the blue light top lid during spin, it will switch suddenly the low speed motor windings obtaining a fast drum speed decrease to wash speed for safety reasons.

Eventually unwanted, by an user, parts of the washing program may be cutted out or skipped pushing one more time the "1" button until the program progress indicator nail moves on the desired position. This allows to create personalized programs by skipping parts until the user will do so.

The machine IGN

IS K563 SUPERAUTOMATICA is illustrated in the figures but typically it

can comprise a drum mounted on a shaft in bearings so as to be rotatable

on a horizontal axis within a liquid containing cylinder which is

suspended by means of cooperating springs and dampers absorbers within an outer

cabinet.

IS K563 SUPERAUTOMATICA is illustrated in the figures but typically it

can comprise a drum mounted on a shaft in bearings so as to be rotatable

on a horizontal axis within a liquid containing cylinder which is

suspended by means of cooperating springs and dampers absorbers within an outer

cabinet.It's entirely driven by an HOLZER TIMER (Inventor: Walter HOLZER) AT126 which comprises all devices to perform fully automatic control of the machine electromecanically, and all Patents for all of the systems have had exclusive feature on the IGNIS K563 SUPERAUTOMATICA .

The motor of the IGNIS K563 SUPERAUTOMATICA is a double concentric rotor / stator type with 18 poles for wash speed (260 rpm) and a 2 poles for spin speed (2850 rpm) and was created by engineer Renato Biglino under the Patent as Brevetto Biglino.

Was fabricated in a factory called ELVA (ELettromeccanica VAresina) and in a factory called GIO-BO (GIOvanni BOrghi) and someway even by Ansaldo Motori.

It has 2 resistors of 1300W each one to warm up water and the timer stops advancing until requested temperature is reached, in the mean time cadences of wash revolutions are set up accordigly to wash & pause.

Drain pump is electrical and it's directly mounted on the down side of the tub in a sump.

The cabinet is a highly very heavy and very robust undestroyable ceramic /porcelain enamel steel sheet rust free.Vitreous enamel, also porcelain enamel in US English, is a material made by fusing ... such as some cooking vessels, dishwashers, laundry machines, sinks, and tubs. This invention relates to an enamelling process with porcelain enamel powder coating, particularly for two-layer enamelling, by electrostatically spraying ground-coat and surface-coat powders, followed by common baking, provides an improved one coat,porcelain enamel frit composition which evidences excellent chemical durability and adherence while at the same time having good workability properties so that a relatively thin enamel lining on the order of 5 to 6 mils in thickness can be provided without evidence of pinhole or copperheading defects. At a thickness of one to two mils, the enamel coating of the present invention is also characterized by a rather unique surface appearance, having'a leather-like texture which may be due to its ability to take up iron oxide from the surface of the sheet steel.

The improved porcelain enamel frit of the present application contains a major proportion of silica, together with controlled amounts of titania, boric oxide, sodium oxide, lithium oxide, calcium oxide, cobalt oxide, manganese ice oxide, and fluorine. In the preferred embodiment, the frit also contains small controlled amounts of zirconia, potassium oxide, and nickel oxide. While all of these compounds have previously been employed in porcelain enamel frits for lining hot water tanks, the frit of the present invention contains a balance between the various oxides in the composition which has been found to be responsible for the substantially improved workability properties which characterize the enamel coatings produced from the frits of the present invention.

The IGNIS K563 weights more than 110KG.

in Varese, Italy, Giovanni Borghi builds a factory for 200

employees to manufacture not only ovens and cooktops, but

also an appliance previously unknown in Italy: the refrigerator.

Ignis workers produce appliances for third-party companies

like Fiat, Atlantic, Philco, Emerson and Philips. Borghi builds

the “Villages of Ignis,” with affordable one- and two-family

houses (Borghi Villages), as well as a pool and sports center

in Comerio, Italy, and a hostel vvith recreational facilities for

young workers in Cassinetta, Italy, all intended to promote a

comfortable, healthy lifestyle.

The Milan industrialist Giovanni Borghi founded the IGNIS brand of household appliances. His factories would turn out one appliance every eight seconds, and make billions selling them to Italy's exploding middle class. Borghi was famous for his early support of cycling, and his yellow IGNIS jerseyed squadra won more than a few great races in the late fifties and early sixties.

The Milan industrialist Giovanni Borghi founded the IGNIS brand of household appliances. His factories would turn out one appliance every eight seconds, and make billions selling them to Italy's exploding middle class. Borghi was famous for his early support of cycling, and his yellow IGNIS jerseyed squadra won more than a few great races in the late fifties and early sixties.Borghi was aggressive, flamboyant and flashy. And he took care of his stars - famously buying Spanish sprinter Miguel Poblet a Lancia convertible after his Milan San Remo win. On top of his 25 million lire per year salary.

illumination: refrigerators insulated with Polyurethane foam were much more

efficient and capacious than those hand-filled with mineral wood.

His refrigerators Group, Ignis, developed internally this technology and the

related equipment, a suitable alternative to the imported foam dispensers, which

were difficult to get, fix and maintain, stimulating an industrial supply of

similar machines.

Borghi kept control of IGNIS in the family. In the paternalistic Italian industrial model - like Ferrari, Maserati or Campagnolo. He later turned the reins over to his son, who in turn finally sold the company to Dutch conglomerate, Philips.

When Philips decided to get into the major household appliances

market, its procedure was to buy increasing quantities of these goods from the Italian firm, Ignis, then at the height of its prosperity.

Once it became the principal client of the manufacturer, it took over supplying the latter by purchasing 50 percent of its capital. It took over the firm completely in 1972, to the satisfaction of the founder of Ignis, Giovanni Borghi.

Borghi is still remembered in Italia. RAI even aired TV miniseries about his life this past year, "Mister Ignis".

No comments:

Post a Comment