During the motor drive time, motor velocity is proportional to the applied energizing voltage for constant loads. As the load of the motor changes the motor velocity will be controlled as a function of applied energizing voltage by sensing the back emf and comparing the back emf signal with a commanded motor velocity signal. By controlling the motor with the back emf, it is thus possible to have a very precise and constant motor velocity for changing loads by varying the level of applied energizing voltage. An advantage of the present invention is thus to provide velocity regulation of a motor that is reasonably constant for a commanded input signal, even though the motor may inherently have poor speed regulation if constant voltage is applied because of D.C. motor. The amount of power a motor is required to deliver has little effect on motor velocity.

To control motor velocity with the Control Unit of the present invention the behavior of a rotating armature in a field to generate a back emf is utilized. If the armature isn't moving through the field, then there is no back emf and the level of any generated back emf is an immediate indication of the operation of the motor (In example when NO self restart of the drum is mandatory performed when stopped during distribution / spind-drain and or spinning). The Control Unit of the present invention does not rely on a signal provided by an independent generator, but rather utilizes the basic operation of the motor. There is also no reliance on the variation in armature resistance, which as explained, may vary with armature construction. Furthermore the speed of the motor is resulting as indipendent of the Mains supply voltage for the aformementioned features.

The control circuit constructed as briefly described is mainly composed by a command circuit, a control circuit and a power circuit with diodes and thyristors and this circuit complex composition enables the motor rotational speed to be measured as a function of the voltage taken across the motor terminals with due allowance made for the armature losses arising in the motor. In this manner the regulation of said rotational speed is much highly more accurate under any load condition than that which can be obtained by known electric motor control devices and/or circuits. In addition the circuit described in the present patent prevents the motor absorbing mains power to any extent which could lead to mechanical instability of the washing machine.

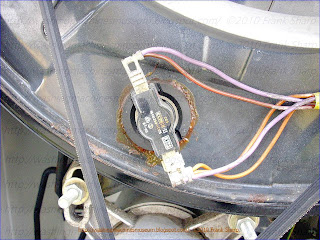

The machine IGNIS K15 (PHILIPS) AWF633/IG P.M. SYSTEM is illustrated in the figures but typically it

can comprise a drum mounted on a shaft in bearings so as to be rotatable

on a horizontal axis within a liquid containing cylinder which is

suspended by means of cooperating springs and dampers within an outer

cabinet. A DC electric drive motor of the series-type is secured to the

liquid containing cylinder and is drivingly connected by means of a `V`

or multi-V belt-drive system to a pulley wheel secured to the drum shaft

outside the liquid cylinder. The system is such that the drum is

rotated at a speed below the motor speed and in a fixed relationship of

say 1:10 or thereabout. Liquid may be supplied to the cylinder through

an electromagnetically actuated inlet valve and removed by an electric

motor-driven pump. Liquid in the cylinder may be heated by an electric

sheathed wire heating element mounted in a lower wall of the cylinder,

the heating element being disposed within the cylinder.

The machine IGNIS K15 (PHILIPS) AWF633/IG P.M. SYSTEM is illustrated in the figures but typically it

can comprise a drum mounted on a shaft in bearings so as to be rotatable

on a horizontal axis within a liquid containing cylinder which is

suspended by means of cooperating springs and dampers within an outer

cabinet. A DC electric drive motor of the series-type is secured to the

liquid containing cylinder and is drivingly connected by means of a `V`

or multi-V belt-drive system to a pulley wheel secured to the drum shaft

outside the liquid cylinder. The system is such that the drum is

rotated at a speed below the motor speed and in a fixed relationship of

say 1:10 or thereabout. Liquid may be supplied to the cylinder through

an electromagnetically actuated inlet valve and removed by an electric

motor-driven pump. Liquid in the cylinder may be heated by an electric

sheathed wire heating element mounted in a lower wall of the cylinder,

the heating element being disposed within the cylinder. In operation of the washing machine its various functions are sequentially controlled by a program controller comprising a synchronous electric timer motor actuating, via a stepping linkage, a number of cams and hence switches which control the supply of electrical power to the various parts of the machine in sequence so as to cause a particular program of operations to be performed on clothes placed in the drum, and a solid state switching circuit, also controlled by the timer motor for the drive motor of the machine, which controls the speed and acceleration of the drum motor.

This invention relates to clothes-washing and spin-drying machines and

relates especially though not exclusively to such machines of the type

in which clothes can be washed in a drum by means of a tumbling action

effected by rotating the drum about a horizontal or at least inclined

axis at a relatively low speed in the presence of washing liquid and can

subsequently be dried by a spinning operation achieved by rotating the

drum about the same axis at a comparatively high speed.

This invention relates to clothes-washing and spin-drying machines and

relates especially though not exclusively to such machines of the type

in which clothes can be washed in a drum by means of a tumbling action

effected by rotating the drum about a horizontal or at least inclined

axis at a relatively low speed in the presence of washing liquid and can

subsequently be dried by a spinning operation achieved by rotating the

drum about the same axis at a comparatively high speed. A problem associated with such washing and spin-drying machines is the prevention of excessive out of balance forces on the drum during high-speed spinning due to clothes accumulating at one point in the drum. With lower spinning speeds the problem can be overcome by incorporating a suspension for the outer container of such a design that out of balance forces are absorbed. However, at higher spinning speeds, which are, in any event, desirable for the successful drying of the clothes, this solution is not practicable and arrangements must be made to ensure that the clothes drum is not excessively out of balance during such high-speed rotation. This may be achieved by making the clothes drum such that it is self-balancing-- but that reduces the possible size and hence the capacity of the drum. Alternatively it can be arranged that whenever the clothes drum is required to rotate at a high spinning speed this operation is preceded by rotation of the drum at a low washing speed in the same direction. This solution is not entirely satisfactory, however, as the speed for washing the clothes must be low enough to cause the clothes to tumble and not cling to the drum wall, i.e., the centrifugal force on the clothes must be less than the gravitational force, and as a result the clothes are not evenly distributed around the drum wall, as is desired, if the drum is to be in a balanced condition for the subsequent high-speed spinning operation.

It is therefore desirable that the drum be rotated at a speed intermediate the tumbling speed and the spinning speed for a short time prior to spinning the drum at high speed in order to ensure that the clothes distribute themselves equally around the internal periphery of the drum in a balanced manner. This has been achieved, for example, by providing a drive motor for the drum capable of energization at three speeds, these speeds being selected by a control arrangement for the machine such that, on termination of a tumbling action provided by rotation of the motor at its lowest speed the spin action provided by the motor rotating at

its highest speed is preceded by a short period of rotation at an

intermediate speed where the weight of the clothes is just balanced by

the centrifugal force on the clothes at this speed, the desired result

being that the clothes cease to tumble within the drum and contact the

inner peripheral wall of the drum in a balanced manner. The drive motor

is then accelerated to its highest (spinning) speed. A problem inherent

in this arrangement is that there is no certainty that the clothes will

distribute themselves in a balanced manner in the drum during the period

of rotation at the intermediate speed, as the comparatively rapid

acceleration of the drum from tumbling speed to this intermediate speed

tends to fling the clothes abruptly outwards to the wall of the drum in

the pattern of distribution which they adopt for the previous tumbling

operation (which is very rarely uniform). As a result of this the

acceleration to spinning speed results in large out of balance forces on

the drum.

its highest speed is preceded by a short period of rotation at an

intermediate speed where the weight of the clothes is just balanced by

the centrifugal force on the clothes at this speed, the desired result

being that the clothes cease to tumble within the drum and contact the

inner peripheral wall of the drum in a balanced manner. The drive motor

is then accelerated to its highest (spinning) speed. A problem inherent

in this arrangement is that there is no certainty that the clothes will

distribute themselves in a balanced manner in the drum during the period

of rotation at the intermediate speed, as the comparatively rapid

acceleration of the drum from tumbling speed to this intermediate speed

tends to fling the clothes abruptly outwards to the wall of the drum in

the pattern of distribution which they adopt for the previous tumbling

operation (which is very rarely uniform). As a result of this the

acceleration to spinning speed results in large out of balance forces on

the drum. Conveniently a controlled semiconductor rectifier device such as a thyristor is provided in series with the electric motor with respect to input terminals which are arranged to be con

nected

to an alternating current supply, electric pulses being arranged to be

applied to the gate of the device in appropriate half-cycles of the

alternating current supply to fire the device and cause driving power to

be supplied to the motor.

nected

to an alternating current supply, electric pulses being arranged to be

applied to the gate of the device in appropriate half-cycles of the

alternating current supply to fire the device and cause driving power to

be supplied to the motor. The control means in such a case is conveniently formed with solid state control elements, in particular transistors, so connected and arranged as to control the conduction angle or mark-to-space ratio of the pulses applied to the motor from the semiconductor rectifier device.

The control means preferably also includes feedback means which normally tend to maintain the motor rotating with a selected constant slow speed, said time-dependent means being arranged to override the feedback means when a spin drying operation is initiated.

It will be understood that the invention also includes within its scope control units for controlling the speed of an electric motor driving the clothes drum of a clothes-washing and spin-drying machine or a spin-drying machine in accordance with the invention.

A problem associated with such washing and spi

n-drying machines is the

prevention of excessive out of balance forces on the drum during

high-speed spinning due to clothes accumulating at one point in the

drum. With lower spinning speeds the problem can be overcome by

incorporating a suspension for the outer container of such a design that

out of balance forces are absorbed. However, at higher spinning speeds,

which are, in any event, desirable for the successful drying of the

clothes, this solution is not practicable and arrangements must be made

to ensure that the clothes drum is not excessively out of balance during

such high-speed rotation. This may be achieved by making the clothes

drum such that it is self-balancing-- but that reduces the possible size

and hence the capacity of the drum. Alternatively it can be arranged

that whenever the clothes drum is required to rotate at a high spinning

speed this operation is preceded by rotation of the drum at a low

washing speed in the same direction. This solution is not entirely

satisfactory, however, as the speed for washing the clothes must be low

enough to cause the clothes to tumble and not cling to the drum wall,

i.e., the centrifugal force on the clothes must be less than the

gravitational force, and as a result the clothes are not evenly

distributed around the drum wall, as is desired, if the drum is to be in

a balanced condition for the subsequent high-speed spinning operation.

n-drying machines is the

prevention of excessive out of balance forces on the drum during

high-speed spinning due to clothes accumulating at one point in the

drum. With lower spinning speeds the problem can be overcome by

incorporating a suspension for the outer container of such a design that

out of balance forces are absorbed. However, at higher spinning speeds,

which are, in any event, desirable for the successful drying of the

clothes, this solution is not practicable and arrangements must be made

to ensure that the clothes drum is not excessively out of balance during

such high-speed rotation. This may be achieved by making the clothes

drum such that it is self-balancing-- but that reduces the possible size

and hence the capacity of the drum. Alternatively it can be arranged

that whenever the clothes drum is required to rotate at a high spinning

speed this operation is preceded by rotation of the drum at a low

washing speed in the same direction. This solution is not entirely

satisfactory, however, as the speed for washing the clothes must be low

enough to cause the clothes to tumble and not cling to the drum wall,

i.e., the centrifugal force on the clothes must be less than the

gravitational force, and as a result the clothes are not evenly

distributed around the drum wall, as is desired, if the drum is to be in

a balanced condition for the subsequent high-speed spinning operation. It is therefore desirable that the drum be rotated at a speed intermediate the tumbling speed and the spinning speed for a short time prior to spinning the drum at high speed in order to ensure that the clothes distribute themselves equally around the internal periphery of the drum in a balanced manner. This has been achieved, for example, by providing a drive motor for the drum capable of energization at three speeds, these speeds being selected by a control arrangement for the machine such that, on termination of a tumbling action provided by rotation of the motor at its lowest speed the spin action provided by the motor rotating at its highest speed is preceded by a short period of rotation at an intermediate speed where the weight of the clothes is just balanced by the centrifugal force on the clothes at this speed, the desired result being that the clothes cease to tumble within the drum and contact the inner peripheral wall of the drum in a balanced manner. The drive motor is then accelerated to its highest (spinning) speed. A problem inherent in this arrangement is that there is no certainty that the clothes will distribute themselves in a balanced manner in the drum during the period of rotation at the intermediate speed, as the comparatively rapid acceleration of the drum from tumbling speed to this intermediate speed tends to fling the clothes abruptly outwards to the wall of the drum in the pattern of distribution which they adopt for the previous tumbling operation (which is very rarely uniform). As a result of this the acceleration to spinning speed results in large out of balance forces on the drum.

1. A direct current

motor comprising a tubular stator housing and a rotatable rotor member

concentrically arranged within said stator housing, first and second

permanent magnets each having the configuration of a hollow tube sector

and concentrically mounted with their outer walls engaging the stator

housing, first and second magnetic pole pieces each comprising a

longitudinal segment of a cylinder having nonradial sidewalls defining

the circumferential limits of the segment so that the outer

circumferential surface of the segment is at least 11/2 times longer

than its inner surface, and means for concentrically mounting said first

and second segments with their outer surfaces in contact with the inner

surfaces of said first and second magnets, respectively, and with their

inner surfaces facing said rotor to define an air gap therewith thereby

to concentrate the magnetic flux within a given area.

1. A direct current

motor comprising a tubular stator housing and a rotatable rotor member

concentrically arranged within said stator housing, first and second

permanent magnets each having the configuration of a hollow tube sector

and concentrically mounted with their outer walls engaging the stator

housing, first and second magnetic pole pieces each comprising a

longitudinal segment of a cylinder having nonradial sidewalls defining

the circumferential limits of the segment so that the outer

circumferential surface of the segment is at least 11/2 times longer

than its inner surface, and means for concentrically mounting said first

and second segments with their outer surfaces in contact with the inner

surfaces of said first and second magnets, respectively, and with their

inner surfaces facing said rotor to define an air gap therewith thereby

to concentrate the magnetic flux within a given area. 2. A motor as claimed in claim 1 wherein each of said pole pieces are shaped to provide a pair of flat longitudinally extending surfaces, and said mounting means comprises a pair of longitudinally mounted rods for each pole piece and bearing against said flat surfaces.

The present invention relates to a direct current commutator

motor having a tubular stator and energized by permanent magnets.

The present invention relates to a direct current commutator

motor having a tubular stator and energized by permanent magnets. Such motors are frequently used in cases of low power consumption, for example in toys, in devices for driving electric contacts of automatic machines, and the like.

However, if higher powers are to be supplied at

larger voltages, such as in domestic apparatus, energization by means of

electromagnets is still preferred because the rotor can then be

magnetized to saturation. The conventional permanent magnets supply a

flux density which is considerably lower than the saturation density of

iron. For example, magnets made of a material which is known under the

trade name of "Ferroxdure" and has been described in British Pat.

Specification 747,724, supplies a flux density of approximately 0.4 Wb/m2, whereas the saturation density of iron is approximately equal to 1.5 Wb/m2.

The same power can then be supplied only if the insufficiently

magnetized rotor is provided with a larger number of turns and has

larger dimensions, which requires a larger quantity of sheet iron.

However, this problem does not play a part in low-power motors so that

in this case there is no objection to using permanent magnets.

However, if higher powers are to be supplied at

larger voltages, such as in domestic apparatus, energization by means of

electromagnets is still preferred because the rotor can then be

magnetized to saturation. The conventional permanent magnets supply a

flux density which is considerably lower than the saturation density of

iron. For example, magnets made of a material which is known under the

trade name of "Ferroxdure" and has been described in British Pat.

Specification 747,724, supplies a flux density of approximately 0.4 Wb/m2, whereas the saturation density of iron is approximately equal to 1.5 Wb/m2.

The same power can then be supplied only if the insufficiently

magnetized rotor is provided with a larger number of turns and has

larger dimensions, which requires a larger quantity of sheet iron.

However, this problem does not play a part in low-power motors so that

in this case there is no objection to using permanent magnets. The invention has for an object to provide direct current commutator motors for higher powers energized by permanent magnets which magnetize the rotor to saturation. In order to obtain the simplest possible construction of the stator, the latter should have a tubular from. These tubes need not be laminated and may be readily cut from long iron tubes.

A motor, in accordance with the invention, is characterized in that the permanent magnets are each in the form of a hollow tube sector, the outer wall of which engages the stator and the inner wall of which engages a corresponding pole piece along a contact surface which is larger, and preferably more than 11/2 times larger, than the surface along which the pole piece adjoins the air gap.

Due to the apparently extraordinarily large dimensions of the stator when compared with those of the rotor, however, large permanent magnets can be used. The emanating flux is indeed proportional to the flux-emanating surface of the magnet. This flux is then concentrated by means of the pole pieces and passed on to the rotor. Thus, the pole pieces serve not only to prevent the occurrence of stray flux but also to provide a strong flux concentration. The diameter of the rotor may then be chosen to be smaller for a given power to be supplied. Although the dimensions of the stator become slightly larger, the cost price of the assembly as a whole is reduced.

The invention will now be described more fully with reference to the accompanying drawing, in which:

FIG. 1 shows a motor for low voltages and powers energized by permanent magnets.

FIG. 2 shows a motor for higher voltages and powers energized by electromagnets.

FIG. 3 shows a motor according to the invention for higher voltages and powers energized by permanent magnets.

FIG. 4 shows one of the permanent magnets used. Each of these FIGS. is a sectional view at right angles to the motor shaft.

The

motor of FIG. 1 is used for low powers and has a tubular stator 1, two

permanent magnets 2 and 3 supplying the energizing flux and a rotor 4.

Such motors are generally supplied with a direct voltage of 6 volts to

12 volts. In domestic apparatus, such as textile-washing machines,

dough-kneading machines, pumps and the like, powers are required which

exceed 100 watts and for which it is desirable to use direct voltages in

excess of 100 volts. For the reasons set out above, the energization is

supplied by one or more windings 5 (FIG. 2) wound onto a pole piece 6

and electrically energized in series or in parallel with the armature

winding or directly by a fixed direct voltage. In this case the pole

piece serves to minimize the reluctance of the magnetic flux circuit and

the stray flux.

The

motor of FIG. 1 is used for low powers and has a tubular stator 1, two

permanent magnets 2 and 3 supplying the energizing flux and a rotor 4.

Such motors are generally supplied with a direct voltage of 6 volts to

12 volts. In domestic apparatus, such as textile-washing machines,

dough-kneading machines, pumps and the like, powers are required which

exceed 100 watts and for which it is desirable to use direct voltages in

excess of 100 volts. For the reasons set out above, the energization is

supplied by one or more windings 5 (FIG. 2) wound onto a pole piece 6

and electrically energized in series or in parallel with the armature

winding or directly by a fixed direct voltage. In this case the pole

piece serves to minimize the reluctance of the magnetic flux circuit and

the stray flux. The motor according to the invention is shown in FIG. 3 and is used at the same voltages and for the same purposes as the motor of FIG. 2. The rotor employed may also the the same. If the rotor 16 should be used together with a stator in the configuration of FIG. 1, this rotor would not be saturated and would not be utilized to its full voltage capacity. Instead of increasing the dimensions of the rotor or the number of turns, according to the invention, the dimension of the stator are increased and the configuration of the stator is altered so that the rotor can nevertheless be magnetized to saturation.

The increase of the dimensions of the stator 17 permits of also using larger permanent magnets 7, the flux of which is concentrated through pole pieces 8 and is passed on to the rotor 16. The ratio of the flux density at the air gap to the flux density supplied by the magnet 7 is approximately equal to that of the surface of the inner wall 9 of the magnet 7 to the surface along which the pole piece adjoins the air gap 10 if the flux is not concentrated too far beyond the knee of saturation. The desired dimensions of the permanent magnets, the shape and dimensions of the associated pole pieces and of the stator can thus be found. Ratios of from 1.5:1 up to 3:1 are suitable.

The outer wall 18 of each perman

ent magnet engages the inner side of the stator

17. The stator may consist of soft iron of soft steel and need not be

laminated because the flux variations are small. This also applies to

the pole pieces. However, it is sometimes desirable that the pole pieces

be made of sheet iron because the passing rotor teeth produce a certain

alternating flux. The stator is in the form of a tube. This tube may

have a larger length that the magnet. In this case, the same stator

reluctance can be obtained with a thinner tube. The tube may be closed

at both ends with aluminum discs. The permanent magnets are in the form

of hollow tube sectors (FIG. 4) and may be made, for example, of the

aforesaid

ent magnet engages the inner side of the stator

17. The stator may consist of soft iron of soft steel and need not be

laminated because the flux variations are small. This also applies to

the pole pieces. However, it is sometimes desirable that the pole pieces

be made of sheet iron because the passing rotor teeth produce a certain

alternating flux. The stator is in the form of a tube. This tube may

have a larger length that the magnet. In this case, the same stator

reluctance can be obtained with a thinner tube. The tube may be closed

at both ends with aluminum discs. The permanent magnets are in the form

of hollow tube sectors (FIG. 4) and may be made, for example, of the

aforesaid  "Ferroxdure," of strontium ferrite or of a suitable alloy. The

pole pieces and the magnets may be clamped to the stator, for example,

by means of rods 12 secured in the aluminum discs.

"Ferroxdure," of strontium ferrite or of a suitable alloy. The

pole pieces and the magnets may be clamped to the stator, for example,

by means of rods 12 secured in the aluminum discs. As a matter of course, the invention may also be applied to multipolar motors.

A direct current commutator motor having a tubular stator housing, on the inner side of which are arranged curved permanent magnets which are provided with pole pieces, the surface along which the permanent magnets adjoin the pole pieces being larger than the magnetically active surface between the pole pieces and the rotor.

e at a first

comparatively low-washing speed and at a second comparatively

high-spin-drying speed, the improvement comprising an automatic speed

adjusting circuit for said motor comprising, a pair of input terminals

adapted for connection to an AC voltage supply source, a supply circuit

for the motor connected to the input terminals and provided with at

least two further terminals, an electric heating element arranged to

heat the wash water and connected across said two further terminals, a

controlled rectifier connected in the supply circuit so as to regulate

the motor speed at a given washing speed, and means connecting said two

further terminals in the motor supply circuit so that the motor is at

least substantially energized through at least a part of the heating

element whereby it exhibits a speed characteristic which decreases very

sharply with increasing load.

e at a first

comparatively low-washing speed and at a second comparatively

high-spin-drying speed, the improvement comprising an automatic speed

adjusting circuit for said motor comprising, a pair of input terminals

adapted for connection to an AC voltage supply source, a supply circuit

for the motor connected to the input terminals and provided with at

least two further terminals, an electric heating element arranged to

heat the wash water and connected across said two further terminals, a

controlled rectifier connected in the supply circuit so as to regulate

the motor speed at a given washing speed, and means connecting said two

further terminals in the motor supply circuit so that the motor is at

least substantially energized through at least a part of the heating

element whereby it exhibits a speed characteristic which decreases very

sharply with increasing load.  1. In an automatic

washing machine including a commutating electric motor for driving the

drum of the washing machine at a first comparatively low-washing speed

and at a second comparatively high-spin-drying speed, the improvement

comprising an automatic speed adjusting circuit for said motor

comprising, a pair of input terminals adapted for connection to an AC

voltage supply source, a supply circuit for the motor connected to the

input terminals and provided with at least two further terminals, an

electric heating element arranged to heat the wash water and connected

across said two further terminals, a controlled rectifier connected in

the supply circuit so as to regulate the motor speed at a given washing

speed, and means connecting said two further terminals in the motor

supply circuit so that the motor is at least substantially energized

through at least a part of the heating element whereby it exhibits a

speed characteristic which decreases very sharply with increasing load.

1. In an automatic

washing machine including a commutating electric motor for driving the

drum of the washing machine at a first comparatively low-washing speed

and at a second comparatively high-spin-drying speed, the improvement

comprising an automatic speed adjusting circuit for said motor

comprising, a pair of input terminals adapted for connection to an AC

voltage supply source, a supply circuit for the motor connected to the

input terminals and provided with at least two further terminals, an

electric heating element arranged to heat the wash water and connected

across said two further terminals, a controlled rectifier connected in

the supply circuit so as to regulate the motor speed at a given washing

speed, and means connecting said two further terminals in the motor

supply circuit so that the motor is at least substantially energized

through at least a part of the heating element whereby it exhibits a

speed characteristic which decreases very sharply with increasing load.

2. A washing machine as claimed in claim 1 further comprising a switch by which the further terminals can be directly connected to the input terminals in the cutoff condition of the motor, and means connecting the switch across the series combination of the motor and the controlled rectifier.

3. A washing machine as claimed in claim 2 wherein the supply circuit includes a full wave bridge rectifier, means connecting one of the further terminals to one of the input terminals and another one of the further terminals to one of the input terminals of the bridge rectifier, and means connecting the switch between the two input terminals of the bridge rectifier.

4. A washing machine as claimed in claim 1 further comprising a braking switch by which the motor can be connected across the heating element when the motor supply circuit is interrupted.

5. A washing machine as claimed in claim 1 further comprising means for varying the mechanical load on the motor during a given washing cycle.

6. An automatic speed control circuit for a

n electric

motor subject to a wide variation in load during a normal cycle of

operation comprising, a source of supply voltage, said motor having a

given speed torque characteristic if connected to said supply voltage

such that it exhibits a given speed variation between the expected

minimum and maximum values of load, means for varying the load on the

motor between said minimum and maximum load values during a normal cycle

of operation of the motor, a controlled rectifier connected in series

with the motor, means for adjusting the firing angle of said controlled

rectifier as a function of motor speed so as to regulate the motor speed

at one of said load values, a resistor, and means connecting at least a

part of said resistor in series with the motor across said voltage

source so that the speed characteristic of the motor is changed to

substantially increase said given speed variation between said expected

minimum and maximum values of load.

n electric

motor subject to a wide variation in load during a normal cycle of

operation comprising, a source of supply voltage, said motor having a

given speed torque characteristic if connected to said supply voltage

such that it exhibits a given speed variation between the expected

minimum and maximum values of load, means for varying the load on the

motor between said minimum and maximum load values during a normal cycle

of operation of the motor, a controlled rectifier connected in series

with the motor, means for adjusting the firing angle of said controlled

rectifier as a function of motor speed so as to regulate the motor speed

at one of said load values, a resistor, and means connecting at least a

part of said resistor in series with the motor across said voltage

source so that the speed characteristic of the motor is changed to

substantially increase said given speed variation between said expected

minimum and maximum values of load. 7. A control circuit as claimed in claim 6 for use in an auto

matic washing machine and further comprising a programming device

controlling said load varying means and the wash cycle, means controlled

by said programming device for periodically deactivating the motor

during a wash cycle, and switching means controlled by the programming

device for selectively connecting said resistor directly across the

voltage source during the time the motor is deactivated during a wash

cycle.

matic washing machine and further comprising a programming device

controlling said load varying means and the wash cycle, means controlled

by said programming device for periodically deactivating the motor

during a wash cycle, and switching means controlled by the programming

device for selectively connecting said resistor directly across the

voltage source during the time the motor is deactivated during a wash

cycle. 8. A control circuit as claimed in claim 7 wherein said resistor is a heating element located so as to heat the wash water, said circuit further comprising a braking switch for selectively connecting the heating element across the motor in the event that the motor supply circuit is opened.

This invention relates to an arrangement including a commutating

electric motor for driving the drum of a washing machine provided with

at least one electric heating element, especially an automatic washing

machine having at least one comparatively low-washing speed and also at

least one comparatively high-spin-drying speed, which arrangement has a

pair of input terminals for connection to a source of supply voltage and

a supply circuit for the motor connected to these terminals.

This invention relates to an arrangement including a commutating

electric motor for driving the drum of a washing machine provided with

at least one electric heating element, especially an automatic washing

machine having at least one comparatively low-washing speed and also at

least one comparatively high-spin-drying speed, which arrangement has a

pair of input terminals for connection to a source of supply voltage and

a supply circuit for the motor connected to these terminals. Such arrangements are known and are at present used in most automatic washing machines. At least two widely different speeds (ratios of the order of 1:20 or more are commonly used) are obtained in various manners, for example, by means of two different motors, by means of a kind of gearbox having at least two speeds, by the use of two or more belt or cord drives with different ratios or by a transformer provided with tappings enabling a single motor to be energized with different voltages.

It is an object of the invention to provide a simplified, particularly lightweight and cheap and yet reliable arrangement of the aforementioned kind. The invention is based on the experience that when a self-commutating electric motor is energized through a resistor of sufficient value its load can be increased to an extent such that, it runs regularly at an unexpectedly low speed without exceeding the permissible motor current. In other words, the motor acquires a kind of highly exaggerated series characteristic. The invention is also based on the recognition that just this characteristic is very useful in a washing machine because, during the washing operation, when the tub is full of water which must be kept hot or be heated, the motor is heavily loaded and will consequently run at a low speed and consume

much current. As a result, the energy dissipated in a

series resistor will be large and may be utilized for heating or keeping

the water hot, whereas during the spin-drying operation, when the water

has been discharged from the tub, the motor is only lightly loaded and

will reach a high speed while consuming little current so that the

energy dissipated in a series resistance will be comparatively small and

can readily be removed, even without water cooling.

much current. As a result, the energy dissipated in a

series resistor will be large and may be utilized for heating or keeping

the water hot, whereas during the spin-drying operation, when the water

has been discharged from the tub, the motor is only lightly loaded and

will reach a high speed while consuming little current so that the

energy dissipated in a series resistance will be comparatively small and

can readily be removed, even without water cooling. The arrangement in accordance with the invention is characterized in that it is provided, in addition to the aforementioned input terminals, with at least two further terminals for the connection of a heating element of the washing machine. The latter terminals are included in the motor supply circuit so that the motor is at least substantially energized through at least part of this heating element, whereby it exhibits a speed characteristic which very strongly decreases with increasing load.

It should be noted that it is known from the U.S. Pat. No. 1,998,670 to feed an electric motor through a heating element. This patent is however concerned with a fan motor which serves to maintain the air circulation about a heating element of an electric stove in order to provide a better distribution of heated air by forced convection. Consequently, this motor operates with a substantially constant small load and always runs at a normal, comparatively high speed, so that it does not make use of an exaggerated series characteristic and/or of the aforementioned related useful effects occurring in a washing machine.

The invention may be used with any kind of commutating motor: with commutator motors provided with series shunt or compound energization or energization by a permanent magnet fed with smoothed or unsmoothed direct current or with alternating current, or with motors having a rotating permanent magnet, for example, with commutatorless motors provided with an electronic commutator, for example, motors using Hall plates as control elements.

During a washing cycle the load on the motor varies with the amo

unt of washing

goods with which the drum of the washing machine is filled and/or with

the level of the water in the tub of the machine, whereas the washing

effect is an optimum at a given speed of revolution. Therefore the

arrangement preferably includes a known control device by which the

motor speed is regulated at at least one washing speed. In an

arrangement for connection to an alternating voltage supply source, this

control device may, for example, include a controlled rectifier by

which the motor speed is regulated.

unt of washing

goods with which the drum of the washing machine is filled and/or with

the level of the water in the tub of the machine, whereas the washing

effect is an optimum at a given speed of revolution. Therefore the

arrangement preferably includes a known control device by which the

motor speed is regulated at at least one washing speed. In an

arrangement for connection to an alternating voltage supply source, this

control device may, for example, include a controlled rectifier by

which the motor speed is regulated. Features and advantages of the invention will appear from the following description of embodiments thereof, given by way of example only, with reference to the accompanying drawings, in which:

FIG. 1 is a circuit diagram showing the basic elements of a simple embodiment of an arrangement in accordance with the invention,

FIG. 2 shows the speed vs. torque characteristic of the motor of the arrangement shown in FIG. 1 compared with the characteristic of a conventional series-energized commutator motor.

FIG. 3 is a circuit diagram showing the basic elements of an automatic washing machine equipped with a second embodiment of the arrangement in accordance with the invention,

FIG. 4 is a circuit diagram of a third embodiment, and

FIG. 5 is a circuit diagram of a fourth embodiment of the arrangement in accordance with the invention.

I

n

the simplest possible embodiment shown in FIG. 1, the arrangement

according to the invention comprises a commutating electric motor 1, for

example, a motor with permanent-magnet energization. It further

comprises a pair of input terminals 2, 2' for connection to a voltage

supply source and a supply circuit 3, 3', 4 for the motor 1 connected to

the said terminals. According to the invention the arrangement is

provided with two further terminals 5 and 6 for the connection of a

heating element 7 of the washing machine. These terminals 5, 6 are

included between the parts 3 and 3' of the motor supply circuit 3, 3', 4

so that the motor 1 is energized through the heating element 7.

n

the simplest possible embodiment shown in FIG. 1, the arrangement

according to the invention comprises a commutating electric motor 1, for

example, a motor with permanent-magnet energization. It further

comprises a pair of input terminals 2, 2' for connection to a voltage

supply source and a supply circuit 3, 3', 4 for the motor 1 connected to

the said terminals. According to the invention the arrangement is

provided with two further terminals 5 and 6 for the connection of a

heating element 7 of the washing machine. These terminals 5, 6 are

included between the parts 3 and 3' of the motor supply circuit 3, 3', 4

so that the motor 1 is energized through the heating element 7. In a practical embodiment the motor 1 was a motor provided with permanent-magnet energization rated for a DC supply voltage of 220 volts, with a maximum current of 6.4 amperes at a heavy load and designed for driving the drum of a washing machine at a spin-drying speed of 800 revolutions per minute. The heating element 7 had a resistance value of 32 ohms and was proportioned to be likewise connected to a 220 volts supply voltage in the case of water cooling.

Line A of FIG. 2 shows the speed-torque characteristic (speed n as a function of the load torque K) of the motor 1 of the arrangement shown in FIG. 1 when supplied with a direct voltage of 220 volts through the heating element 7 having a resistance value of 32 ohms.

Curve B of FIG. 2 shows, by way of comparison, the characteristic of a conventional series-energized commutator motor supplied directly with a direct voltage of 220 volts.

At a small load, which corresponds to the spin-drying operation, the motor 1 runs at a speed of 800 revolutions per minute and this speed can increase only by a small amount (to about 900 revolutions per minute) at a theoretical zero load torque. Under a heavy load (k=8, which corresponds to a current of 6.4 amperes) this motor runs at a constant speed of only 50 revolutions per minute. The attained speed ratio is thus 16 to 1.

By way of comparison the curve B of FIG. 2 shows that with a conventional series-energized commutator motor directly fed with its rated voltage, the ratio between normal speed at a small load, which corresponds to the spin-drying operation (K=1), and the speed at the maximum permissible load (K=8) is not even 2 to 1.

In a washing machine the characteristic A provides many important advantages:

a. changing from a low-washing speed to a high-spin-drying speed or vice versa can be automatically effected by decreasing or increasing the load by draining or filling the tub with water.

b. The peak starting current of the motor is limited by the resistance of the heating element.

c. Acceleration to the spin-drying speed is very gradual, especially if the motor is started before the tub has been completely drai

ned.

Consequently, the mechanical starting shock is heavily damped or even

entirely suppressed while the articles to be washed are distributed

about the drum in an optimum manner since the speed increases slowly

during the draining of the tub.

ned.

Consequently, the mechanical starting shock is heavily damped or even

entirely suppressed while the articles to be washed are distributed

about the drum in an optimum manner since the speed increases slowly

during the draining of the tub. d. The resistance of the heating element prevents the motor from reaching an excessive spin-drying speed, for example, in the case of an abnormally high-supply voltage, and protects the arrangement in the case of a short circuit of the motor and/or of its supply circuit and/or if the drum locks.

e. The energy dissipated in the heating element is largest during the washing operation when the water in the tub must be heated or kept hot, but during the spin-drying operation it is so small that it can readily be carried away by the air then contained in the tub without inconvenience for the element, the machine and/or the articles being washed.

f. Finally, when the supply circuit of the motor is interrupted, the motor can rapidly be brought to a standstill by short circuiting it through the heating element so that much more costly protection devices can be economized.

The automatic washing machine th

e basic circuit

diagram of which is shown in FIG. 3 includes a second embodiment of the

arrangement in accordance with the invention. In this embodiment the

motor supply circuit includes a first changeover switch 8, for example,

in the form of a relay changeover contact, by means of which the heating

element can be directly connected across an alternating-voltage supply

2, 2' to speed up the heating of the water contained in the tub of the

machine. This supply circuit includes, in series with the switch 8, a

double-pole changeover switch 10, 10', for example, likewise in the form

of relay changeover contacts capable of reversing the direction of the

current flowing through the motor 1 and hence the direction of rotation

of this motor, and a controlled semiconductor rectifier or thyristor 9

by means of which, at at least one washing speed, the motor speed is

regulated by simple controlled rectification of the current flowing

through the heating element 7 and the motor 1.

e basic circuit

diagram of which is shown in FIG. 3 includes a second embodiment of the

arrangement in accordance with the invention. In this embodiment the

motor supply circuit includes a first changeover switch 8, for example,

in the form of a relay changeover contact, by means of which the heating

element can be directly connected across an alternating-voltage supply

2, 2' to speed up the heating of the water contained in the tub of the

machine. This supply circuit includes, in series with the switch 8, a

double-pole changeover switch 10, 10', for example, likewise in the form

of relay changeover contacts capable of reversing the direction of the

current flowing through the motor 1 and hence the direction of rotation

of this motor, and a controlled semiconductor rectifier or thyristor 9

by means of which, at at least one washing speed, the motor speed is

regulated by simple controlled rectification of the current flowing

through the heating element 7 and the motor 1. Apart from the above-described arrangement the automatic washing machine includes a motor governor 11 by which the thyristor 9 is controlled during the washing operation so that the motor 1 drives the drum of the machine at a substantially constant speed of, say, 50 revolutions per minute. The machine further includes a reversing circuit 12 which controls the switches 8 and 10, 10' so that, during the washing operation the motor 1 alternately and with time intervals rotates in one direction and then in the other direction whereby, during the heating and during the time intervals, the switch 8 can be brought into its lower position so that, if required, a larger electric power is dissipated in the heating element.

The automatic washing machine is provided with a second motor 13 which drives a water pump capable of draining the machine tub. This motor is controlled by a switch 14, for example, a relay contact, which is in turn controlled by a programming device.

The programming device, which also is shown diagrammatically only, comprises a cycle counter 16 by which three electronic switching devices are operated in the correct sequence:

a filling device 17 by which two water supply valves 18 and 19 are opened in a predetermined order and are closed again when the water in the tub reaches a level determined by a detector 20;

a heater 21 by which the thyristor is cut off when the temperature of the water in the tub measured by a transducer 22, for example, a NTC resistor, reaches a predetermined value, for example, 90° C.;

a pump control device 23, which is controlled by a second water level detector 24.

The cycle of operations of the reversing circuit 12 is also controlled by the cycle counter 16.

The automatic washing machine is provided with a switch 25 which is rendered operative by the pump control device 23 and switches off the machine when the water level measured by the second level detector 24 becomes zero during the spin-drying operation. Finally, the system includes a safety switch 26.

The automatic washing machine described can carry out, for example, the following program:

After switching on, the first program cycle (preliminary washing) commences: the tub is first filled with water, with the addition of a washing agent as the case may be, through the first valve 18.

At the instant at which the correct w

ater level is reached, the motor 1 is started

through the cycle counter 16 and under the control of the heater 21 and

the transducer 22. The operating cycle of the reversing circuit 12 is

such that the motor runs alternately in both directions for periods of

12 seconds with time intervals of 3 seconds. The temperature rises

slowly because the heating element 7 is directly connected to the input

terminals during the short time intervals only, during which it

dissipates a power of, say 3 kilowatts, whereas with a running motor its

dissipation is restricted to, say, 1 kilowatt. When the temperature of

the water reaches a value of, say, 30° C. the motor 13 is switched on

through the counter 16 by the switch 14 and under the control of the

device 23 and the second level detector 24 which switches it out again

as soon as the tub is empty, whereby the motor 1 can be switched out if

desired, for example, by 21, 22, but this is not necessary.

ater level is reached, the motor 1 is started

through the cycle counter 16 and under the control of the heater 21 and

the transducer 22. The operating cycle of the reversing circuit 12 is

such that the motor runs alternately in both directions for periods of

12 seconds with time intervals of 3 seconds. The temperature rises

slowly because the heating element 7 is directly connected to the input

terminals during the short time intervals only, during which it

dissipates a power of, say 3 kilowatts, whereas with a running motor its

dissipation is restricted to, say, 1 kilowatt. When the temperature of

the water reaches a value of, say, 30° C. the motor 13 is switched on

through the counter 16 by the switch 14 and under the control of the

device 23 and the second level detector 24 which switches it out again

as soon as the tub is empty, whereby the motor 1 can be switched out if

desired, for example, by 21, 22, but this is not necessary. The second program cycle (washing) proceeds similarly to the first, with the difference that the tub is now filled through the second valve 19, with washing agent added, and that the cycle of operations of the reversing circuit is changed thro

ugh cycle counter 16, for example, to running for

periods of 3 seconds in alternate directions with time intervals

in-between of 12 seconds, and that a different temperature limit of,

say, 90° C. can be chosen for this program cycle.

ugh cycle counter 16, for example, to running for

periods of 3 seconds in alternate directions with time intervals

in-between of 12 seconds, and that a different temperature limit of,

say, 90° C. can be chosen for this program cycle. The third program cycle (rinsing) proceeds similarly to the first, with the sole difference that the tub is filled again through the second valve 19, but without the addition of washing agent.

The next few (for example, three) program cycles (rinsing) proceed similarly to the third but without heating during the intervals and without the use of the temperature limit, the step controlled by elements 21, 22 being skipped.

The last program cycle (spin-drying) consists in that the motor governor 11 switches to the spin-drying speed before the tub is fully drained by the motor 13. In this process the reversing circuit 12 is rendered inoperative by the cycle counter 16 and a power of only about 150 watts is dissipated in the heating element 7.

When the supply of water to the tub from the drum and from the washing goods ceases, the machine is switched off by the switch 25 and all its components return to their respective rest positions, in which they remain until the machine is started again. If the machine is inadvertently opened during operation, the door or cover auto

matically

switches the safety switch 26 from the operative position shown to the

other position in which it interrupts the lead 4 of the supply circuit

and short circuits the motor 1 through the heating element 7, the switch

8 and the reversing switch 10, 10' so that the motor is vigorously

braked by this circuit and is brought to a standstill within a very

short time (of the order of 3 seconds) even from the highest spin-drying

speed.

matically

switches the safety switch 26 from the operative position shown to the

other position in which it interrupts the lead 4 of the supply circuit

and short circuits the motor 1 through the heating element 7, the switch

8 and the reversing switch 10, 10' so that the motor is vigorously

braked by this circuit and is brought to a standstill within a very

short time (of the order of 3 seconds) even from the highest spin-drying

speed. It should be noted that the motor can also be stopped by cutting off the thyristor 9, in which case no electric power is supplied to the heating element 7 during the intervals. It will have attracted notice that the described automatic washing machine does not include any of the otherwise commonly used time-measuring devices. The cycle counter 16 is simply switched from one cycle to the next under the control of the transducers 20, 22 and 24, and the time-measuring device is replaced by an accurate temperature transducer 22. This provides equally satisfactory or even better washing results than with the use of a more expensive time-measuring device.

FIG. 4 shows a third embodiment of the arrangement in accordance with the invention. This embodiment mai

nly differs from that shown in FIG. 3 by the inclusion of a

full-wave rectifying bridge circuit 30 between the input terminals 2,

2' and the motor supply circuit 3, 3', 4 provided with the further

terminals 5 and 6, between which the heating element 7 is shown.

Furthermore, the changeover switch 8 of FIG. 3 is replaced by a

short-circuiting switch 8', and a flywheel diode 31 is connected across

the motor 1 and the reversing switch 10, 10'.

nly differs from that shown in FIG. 3 by the inclusion of a

full-wave rectifying bridge circuit 30 between the input terminals 2,

2' and the motor supply circuit 3, 3', 4 provided with the further

terminals 5 and 6, between which the heating element 7 is shown.

Furthermore, the changeover switch 8 of FIG. 3 is replaced by a

short-circuiting switch 8', and a flywheel diode 31 is connected across

the motor 1 and the reversing switch 10, 10'. By the use of the supply rectifier 30 the power supplied to the motor and to the heating element 7 through the thyristor during each half cycle of the AC supply voltage is about doubled so that the motor 1 can produce a higher torque, even with increased dissipation in the heating element 7.

The flywheel diode 31 ensures that the thyristor 9 is extinguished between successive half cycles of the AC supply voltage and of the rectified voltage across the output terminals of the full-wave rectifier 30. It may also contribute somewhat to the improvement of the control properties and of the form factor of the arrangement, at least at certain speeds. An embodiment of the motor governor similar to the motor governor 11 of FIG. 3 is shown in detail in FIG. 4. The motor 1 is switched off by means of a switch 32, by which the control electrode of the thyristor 9 can be directly connected to its cathode so that the thyristor can no longer be fired. If electric energy is to be dissipated in the heating element 7 with the motor stationary, the switch 8' can be switched on.

The control electrode of the thyristor is also connect

ed to its anode through a resistor 33 of, say, 4.7 kΩin series

with three Zener diodes 34 having an overall Zener voltage of, say 225

volts and with a diode 35 connected in the forward direction. A control

circuit is connected to the junction point of the diode 35 and the Zener

diodes 34. This comprises a second diode 36 connected in the forward

direction and two further Zener diodes 37 each having a Zener voltage of

7.5 volts. A control switch 38 is connected to the negative lead 4 of

the motor supply circuit. This switch has four positions. In its first

position a it connects the end of the control circuit 36, 37 remote from

the diode 35 to the lead 4. The firing of the thyristor 9 through the

circuit 33, 34, 35 is then delayed by the control circuit 36, 37, so

that the motor 1 runs at a controlled normal washing speed of 50

revolutions per minute stabilized by the counteraction of its back

E.M.F. in the cathode circuit of the thyristor 9.

ed to its anode through a resistor 33 of, say, 4.7 kΩin series

with three Zener diodes 34 having an overall Zener voltage of, say 225

volts and with a diode 35 connected in the forward direction. A control

circuit is connected to the junction point of the diode 35 and the Zener

diodes 34. This comprises a second diode 36 connected in the forward

direction and two further Zener diodes 37 each having a Zener voltage of

7.5 volts. A control switch 38 is connected to the negative lead 4 of

the motor supply circuit. This switch has four positions. In its first

position a it connects the end of the control circuit 36, 37 remote from

the diode 35 to the lead 4. The firing of the thyristor 9 through the

circuit 33, 34, 35 is then delayed by the control circuit 36, 37, so

that the motor 1 runs at a controlled normal washing speed of 50

revolutions per minute stabilized by the counteraction of its back

E.M.F. in the cathode circuit of the thyristor 9. In its second position b the switch 38 connects the junction point of the two Zener diodes 37 to the lead 4 so that the firing of the thyristor 9 is even more delayed by the circuit 36, 37. The back E.M.F. of the motor 1 is compared now to the forward voltage across only one of t

he Zener diodes

37. Accordingly the motor 1 runs at a stabilized, particularly

low-washing speed of only 25 revolutions per minute.

he Zener diodes

37. Accordingly the motor 1 runs at a stabilized, particularly

low-washing speed of only 25 revolutions per minute. In its third position c the switch 38 connects the cathode of the diode 36 to the lead 4 through a resistor 39 of, say, 4.7 kΩ, the Zener diode being short circuited by a switch 40 which is coupled to the switch 38. The back E.M.F. of the motor 1 is then compared to the voltage drop across the resistor 39. If this back E.M.F. is equal to zero (for example at starting), the thyristor 9 becomes conductive as soon as its anode voltage exceeds the sum of the voltage drop across the resistor 33, the threshold voltage of the diode 35 and the threshold voltage of the path between its control electrode and its cathode. The resistor 39 is chosen such that the motor 1 is accelerated to a reduced spin-drying speed of 350 revolutions per minute and continues running at this stabilized speed.

In the positions a and b of a practical embodiment of the arrangement the variations of the motor speed due to load variations (between K=1 and K=8 in FIG. 2) and to variations of the AC supply voltage of ± 10 percent were between -4 and +6 percent, and the speed variations due to variations of the ambient temperature between 26° and 61° C. were between -0.6 percent and +2.1 percent.

In its fourth position d the control switch 38 is

open and renders the control

circuit 36, 37 inoperative while the Zener diodes 34 are short circuited

by the switch 40. The thyristor 9 begins to conduct as soon as its

anode voltage minus the back E.M.F. of the motor 1 exceeds the sum of

the threshold voltages of the diode 35 and of the control

electrode-cathode path of the thyristor. The motor 1 is supplied with

substantially complete half cycles of the AC supply voltage and is

accelerated at an even higher rate than in the third position of the

control switch 38. It reaches a spin-drying speed of 725 revolutions per

minute and continues running at this speed.

open and renders the control

circuit 36, 37 inoperative while the Zener diodes 34 are short circuited

by the switch 40. The thyristor 9 begins to conduct as soon as its

anode voltage minus the back E.M.F. of the motor 1 exceeds the sum of

the threshold voltages of the diode 35 and of the control

electrode-cathode path of the thyristor. The motor 1 is supplied with

substantially complete half cycles of the AC supply voltage and is

accelerated at an even higher rate than in the third position of the

control switch 38. It reaches a spin-drying speed of 725 revolutions per

minute and continues running at this speed. FIG. 5 is a circuit diagram of a fourth embodiment. In this embodiment the rectifying bridge 30 of FIG. 4 is replaced by a rectifying bridge 30' the output terminals of which are directly connected to the input terminals of the reversing switch 10, 10'. The bridge input terminals are connected to the input terminal 2' of the device through the lead 4 of the motor supply circuit and to the further terminal 6 through the lead 3' of the same supply circuit, respectively. In addition, the switch 8' of FIG. 4 is replaced by a changeover swit

ch 8" connected between the input

terminals of the rectifier bridge 30'. This provides the advantage that

the rectifier 30' need not supply the high-heating power to the heating

element 7 when this element is connected to the full supply voltage

through the switch 8". Consequently, the heating element 7 is always fed

with alternating current.

ch 8" connected between the input

terminals of the rectifier bridge 30'. This provides the advantage that

the rectifier 30' need not supply the high-heating power to the heating

element 7 when this element is connected to the full supply voltage

through the switch 8". Consequently, the heating element 7 is always fed

with alternating current. The arrangement includes a third further terminal 6' to which a tapping of the heating element 7 is to be connected and which can alternatively be connected to the further terminal 5 in the absence of such a tapping. The motor governor 11 of FIG. 3 or 33-40 of FIG. 4 is here replaced by a two-position governor provided with a switch 11' by which either part or the whole of the heating element 7 can be short circuited when the rectifier 30' is not short circuited. This switch can, for example, be a normally open contact of a relay energized by an adjustable portion of the back E.M.F. of the motor 1 or of the voltage delivered by a tachogenerator (NOT IN PM SYSTEM) .

it arrangement for a direct-current motor for a washing machine,

which motor is equipped with permanent magnets for starting the spinning

operation from a predetermined direction of rotation of the oscillatory

washing movement for the washing operation, irrespective of any manual

operation of the timer. The operation of the timer and of the voltage

change-over device of the motor are effected independently of one

another by means of one or two motors. The arrangement may be used in

washing machines equipped with direct-current motors which permit of

starting the spinning operation either with the tub filled or with the

tub empty.

it arrangement for a direct-current motor for a washing machine,

which motor is equipped with permanent magnets for starting the spinning

operation from a predetermined direction of rotation of the oscillatory

washing movement for the washing operation, irrespective of any manual

operation of the timer. The operation of the timer and of the voltage

change-over device of the motor are effected independently of one

another by means of one or two motors. The arrangement may be used in

washing machines equipped with direct-current motors which permit of

starting the spinning operation either with the tub filled or with the

tub empty.

2. A washing machine as claimed in claim 1, characterized in that the timer and the reversing switch are independently driven by appropriate means.

3. A washing machine as claimed in claim 2, characterized in that the timer and the reversing switch are driven by at least one alternating current

4. A washing machine control system comprising, a reversible DC motor for driving the washing machine drum at a low reversible wash speed and at a high spin-drying speed in one predetermined direction of rotation, reversing switch means that includes first, second and third switching means coupled to the motor terminals, to the motor electric supply, and to a control winding for controlling the reversing switch means, respectively, said first switching means controlling the direction of motor rotation, said second switching means controlling the motor speed and said third switching means controlling said control

winding, a timer for controlling the

sequence of washer operations and the time duration thereof and

including fourth and fifth switching means connected in parallel with

said second and third switching means, respectively, said timer being

operative to open said fourth and fifth switching means prior to the

start of a spin-drying cycle so that said second and third switching

means assume control of the motor speed and the reversing switch,

respectively, said second and third switching means then being operated

in a predetermined relation to the operation of said first switching

means to a condition to provide said predetermined direction of motor

rotation whereby said second switching means adjusts the electric supply

to provide said high spin-drying speed and said third switching

winding, a timer for controlling the

sequence of washer operations and the time duration thereof and

including fourth and fifth switching means connected in parallel with

said second and third switching means, respectively, said timer being

operative to open said fourth and fifth switching means prior to the

start of a spin-drying cycle so that said second and third switching

means assume control of the motor speed and the reversing switch,

respectively, said second and third switching means then being operated

in a predetermined relation to the operation of said first switching

means to a condition to provide said predetermined direction of motor

rotation whereby said second switching means adjusts the electric supply

to provide said high spin-drying speed and said third switching

5. A control system as claimed in claim 4 further comprising a pair of input terminals connected to a source of AC supply voltage, rectifier means coupling said AC supply terminals to the motor via said first switching means to provide a reversible DC voltage to the motor, and means connecting said parallel connected third and fifth switching means in

6. A control system as claimed in claim 5 wherein said timer is arranged to close said fourth and fifth switching means during a wash cycle thereby to operate the motor alternately in both directions of rotation and at said low washing speed.

In known washing machines the oscillatory rotation movement of the wash-drum is obtained by reversing the direction of rotation of the motor of the machine. It is also known for a washing machine to be driven by a change-pole alternating-current motor in which, by changing over the poles, two speeds are obtainable, the washing speed and the spin-drying speed, the latter being considerably higher than the former. The reversal of the direction of rotation of the motor at the washing speed is achieved by means of a reversing switch included in the control unit of the machine. In automatic or semi-automatic washing machines this control unit ensures the sequence and the duration of the operations to be performed according to a selected program, such as washing, heating, rinsing and spin-drying. In such a cycle, switching from washing to spin-drying is to be effected when the reversing switch is out of the circuit. Frequently this will give rise to locking of the drum because the reversing switch is rendered inoperative before the change-over to the spin-drying speed has been effected.

The commonly used control units comprise a timer which determines the sequence and the duration of the operations and a reversing switch. The timer and the reversing switch are mechanically coupled together and are driven by a single motor. This embodiment permits a saving both in the space occupied and in material used.

In the so-called "thermostatic" machines, the timer is stopped during the heating period, i.e. during the time in which the wash-water has not yet reached the desired temperature. However, during this time, the wash-water must continue to be agitated and hence the wash drum has to perform its oscillatory movement. Consequently, during the stationary period of the program, another driving device is required to rotate the cams which control the reversing contacts until the desired water temperature has been reached. In the timers available so far, either a device which disengages the program part or a two-speed motor is used. The part of the timer which controls the reversal of the movement generally comprises a limited number of switches since the reversal of the direction of rotation in alternating current motors requires only single-pole commutation.

In washing machines equipped with dir

ect-current motors, the motor can be

made to run not only in two directions but also at different speeds by

merely controlling the electric supply. Although this a highly

interesting property, realization gives rise to great switching and

safety problems. This problem may be explained with reference to FIGS. 1

and 2 of the accompanying diagrammatic drawings.

ect-current motors, the motor can be

made to run not only in two directions but also at different speeds by

merely controlling the electric supply. Although this a highly

interesting property, realization gives rise to great switching and

safety problems. This problem may be explained with reference to FIGS. 1

and 2 of the accompanying diagrammatic drawings. The invention will now be described in greater detail with reference to the accompanying drawing, in which:

FIG. 1 schematically shows a double pole switching arrangement for a DC motor,

FIG. 2 schematically shows a modified form of the arrangement of FIG. 1,

FIG. 3 shows a preferred form of the invention, and

FIG. 4 illustrates the cyclical operation of the various switches of the arrangement of FIG. 3.

Double-pole switching of a direct-current motor is shown schematically in FIG. 1. In order to reverse the direction of rotation of the motor, the polarity of the voltage at the motor terminals is reversed by closing either the switches 1 and 3 or 2 and 4.

For example, to bring the wash

drum from the washing speed (say 50 rev/min) to the spin-drying speed

(from 200 to 600 rev/min.) it is sufficient to change the supply

current at the motor terminals and to render the reversin

For example, to bring the wash

drum from the washing speed (say 50 rev/min) to the spin-drying speed

(from 200 to 600 rev/min.) it is sufficient to change the supply

current at the motor terminals and to render the reversin g arrangement

inoperative. If the timer is equipped with a single motor, the reversing

switches will rotate continuously. Hence the reversing arrangement must

be rendered inoperative, resulting in a circuit diagram as shown in

FIG. 2. In this circuit arrangement the program part comprises two

switches 15 and 16 which are present to enable the supply circuit,

including the reversing switches, to be interrupted, and two switches 17

and 18 which must be closed to feed the motor so as to obtain the

required spin-drying speed and the proper direction of rotation, which

must be maintained during the entire spin-drying period. The switches

15, 16, 17 and 18 are controlled by the timer. However, they may lead to

an uncontrolled speed when the timer button is manually operated, and

they also may cause the wrong polarity to be switched into circuit when

the polarity has not yet been reversed. The broken lines of FIG. 2 show

the paths which the current takes when the switches are too quickly

operated.

g arrangement

inoperative. If the timer is equipped with a single motor, the reversing

switches will rotate continuously. Hence the reversing arrangement must

be rendered inoperative, resulting in a circuit diagram as shown in

FIG. 2. In this circuit arrangement the program part comprises two

switches 15 and 16 which are present to enable the supply circuit,

including the reversing switches, to be interrupted, and two switches 17

and 18 which must be closed to feed the motor so as to obtain the